● Driven by chain ● Small space occupuation ● Positioning accuracy and time-saving ● Speed controlled by frequency converter to lift goods automatically ● The lifter has the characteristics of advanced control transmission, reliable and stable performance

● Driven by chain ● Small space occupuation ● Positioning accuracy and time-saving ● Speed controlled by frequency converter to lift goods automatically ● The lifter has the characteristics of advanced control transmission, reliable and stable performance ●Easy maintainance ● Low operation cost ● Low noise running, quiet and comfortable ● Can be used to effortlessly and quickly transport a wide variety of products vertically ● Always carry products in an upright position without the risk of product deformation APOLLO Rotative Vertical Lifter can be integrated into most solutions, providing entry and exit in different directions, as well as multi-in and multi-out. It is not only used for the vertical transport of goods, but also realizes the automatic sorting for goods at different floors in the vertical direction.

●Easy maintainance ● Low operation cost ● Low noise running, quiet and comfortable ● Can be used to effortlessly and quickly transport a wide variety of products vertically ● Always carry products in an upright position without the risk of product deformation APOLLO Rotative Vertical Lifter can be integrated into most solutions, providing entry and exit in different directions, as well as multi-in and multi-out. It is not only used for the vertical transport of goods, but also realizes the automatic sorting for goods at different floors in the vertical direction.Product Introduction:

APOLLO Rotative Vertical Lifter has a modular design with few moving parts and safe enclosed drive. The components are compact in structure and flexible in application. This ingenious product can lift goods to the required height, the product is always transported horizontally, so the product will not be deformed in shape. Help customers to improve production line efficiency and ensure their material handling needs are met and operation costs are reduced.

APOLLO Rotative Vertical Lifter has a modular design with few moving parts and safe enclosed drive. The components are compact in structure and flexible in application. This ingenious product can lift goods to the required height, the product is always transported horizontally, so the product will not be deformed in shape. Help customers to improve production line efficiency and ensure their material handling needs are met and operation costs are reduced.Standard Specifications:

| Item | Specification |

| Run direction | Upward / Downward |

| Infeed direction | Straight infeed / Side infeed |

| Outfeed direction | Straight outfeed / Side outfeed |

| Infeed/Outfeed conveyor | Translation connection/ Turnover connection |

| Minimum infeed height | ≥750mm |

| Maximum lifting height | ≤20m |

| Products maximum size | ≤L600×W400×H400mm |

| Capacity | ≤50kg |

| Throughput | ≤2000 parcels/hour |

| Material | Carbon steel/ Stainless steel |

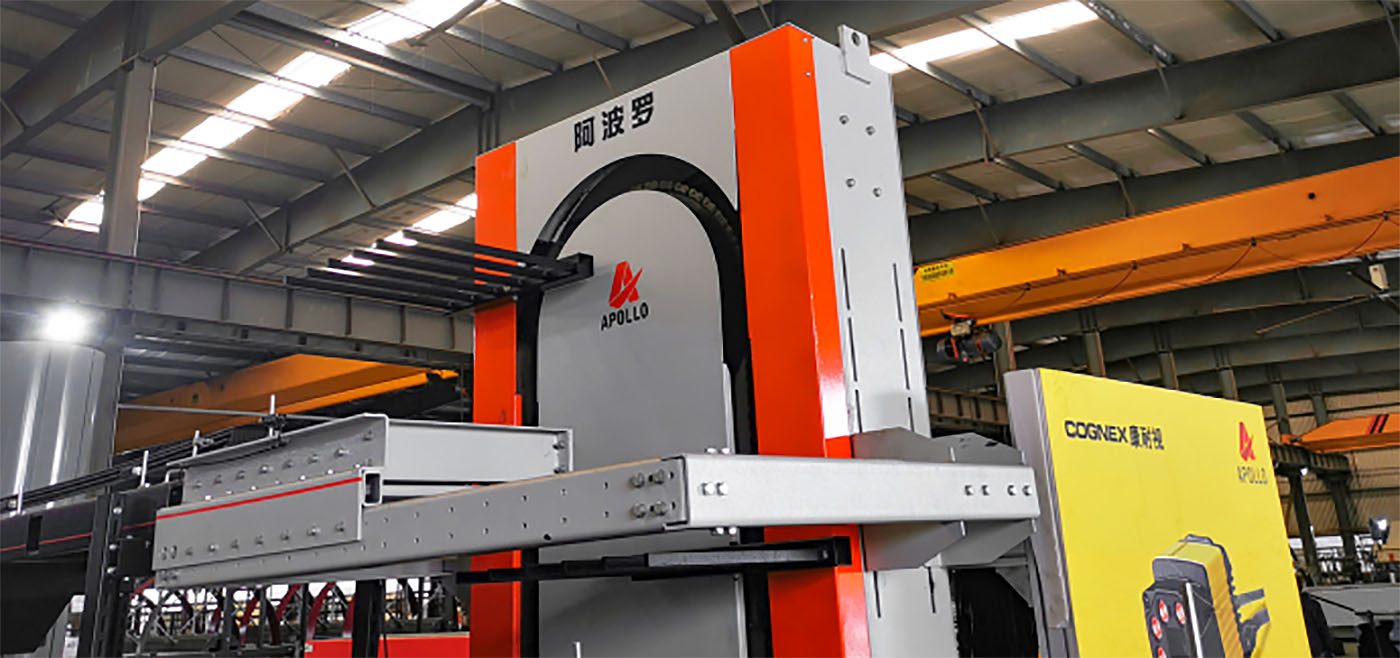

Production Shows:

Frequently Asked Questions:

Factory Show:

More Videos Show (Youtube):

Consumer behavior has changed, supply chains have not. Let's talk today to find perfect design and make your vertical transfer more easy, more safe, more efficiency.

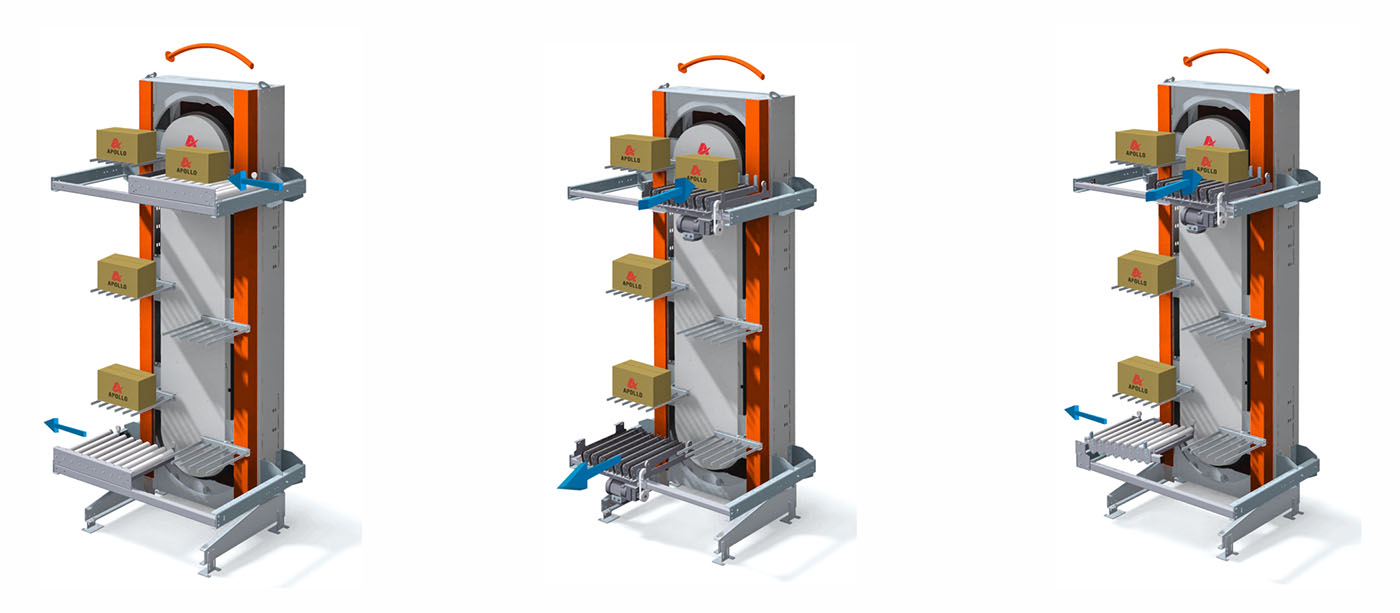

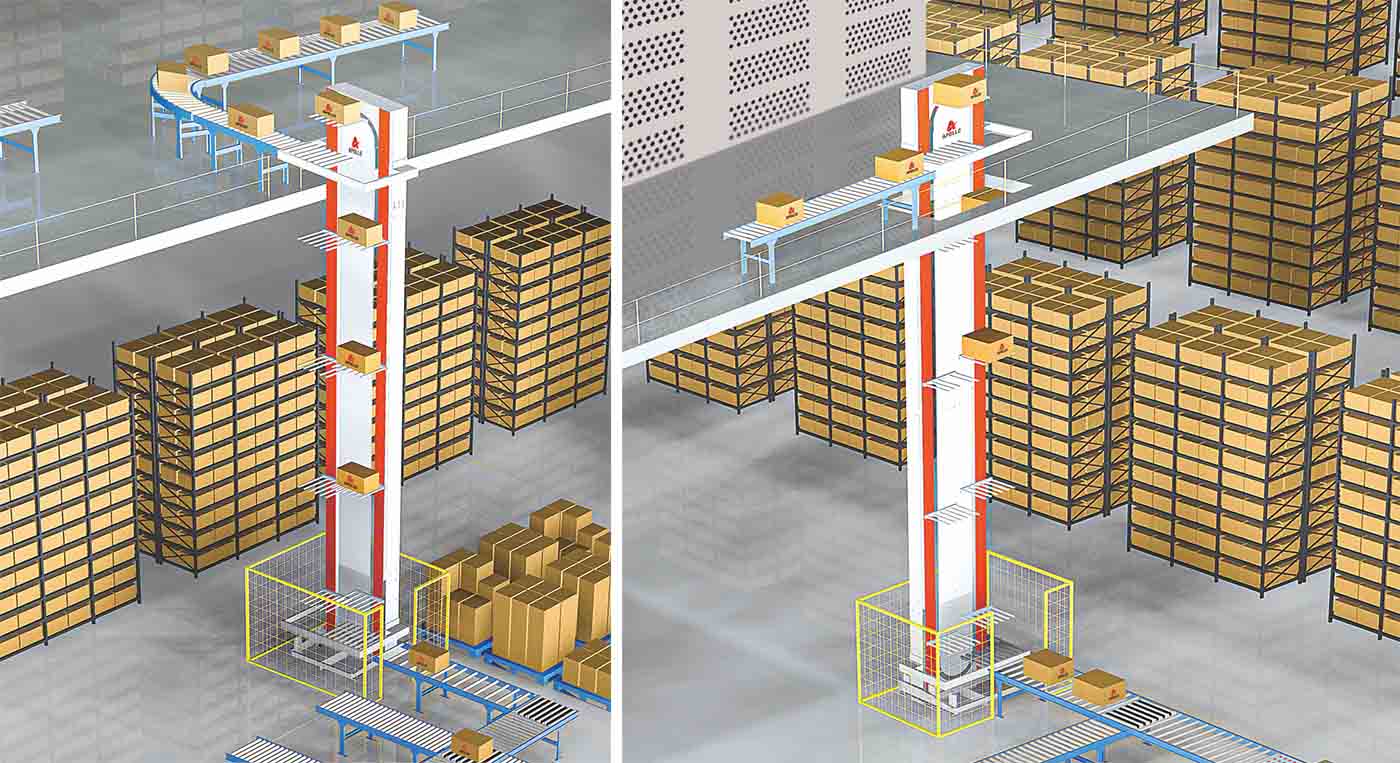

Get in touchIndustry ApplicationsRotative Vertical Lifter is a lifting or descending equipment with good stability and suitable for wide range of goods, mainly used for the transmission of goods between the height difference. Rotative Vertical Lifter and its infeed and outfeed conveyors form a complete of continuous conveying system. It is suitable for vertical transportation of finished products in the fields of logistics, storage, household appliances, food, medicine, tobacco, coating and chemical industry etc. APOLLO design and customize different forms of infeed and outfeed conveyors according to the working process in factory, integrate them seamlessly with other delivery systems. Running direction is either upward or downward. Up type (One in one out)

APOLLO design and customize different forms of infeed and outfeed conveyors according to the working process in factory, integrate them seamlessly with other delivery systems. Running direction is either upward or downward. Up type (One in one out) Down type (One in one out)

Down type (One in one out)